SUMMARY

One Week on "Mars"...

In 2019, I had the unique opportunity to travel with the Medical Makers to the Mars Desert Research Station in Utah, the largest simulated Mars environment and research facility in the world.

I led a research project that explored the technical feasibility of indoor bike-powered 3D printing, to leverage the energy produced by astronauts during their frequent workouts.

My Role: Crew Engineer and Astronomer

Timeline: Jan-March 2019

Tools Used: Python, various electronic equipment (multimeters, wires, generator, charge controller etc.), FDM 3D printer

Various photos of the group and the Mars Desert Research Station terrain.

I want to thank Ennio Colucci and Jade Bilkey for the electronics and programming support, and Julielynn Wong, Dean Jin, Erica Rydberg and David Kim for their participation in the research experiment.

PROBLEM

Power is limited on space missions.

Dust storms on Mars can limit solar charging.

Astronauts must workout 2-3 hours per day on long-term space missions to avoid muscle atrophy caused by 0 gravity, but their energy goes unused even though it could be used to power the spacecraft.

Onboard the ISS, there is a CEVIS (space bicycle) and a 3D printer usually used to print spare parts, tools and emergency medical equipment.

SOLUTION

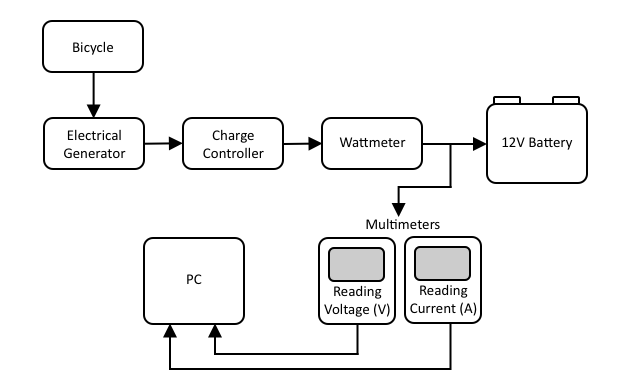

With support from electronics experts, Ennio & Jade, I developed a system involving a road bike and indoor stand, electrical generator, charge controller, wattmeter and 12V battery.

A subject riding the bicycle generates rotational kinetic energy, which is passed through the electrical generator (Pedal-A-Watt system) and charge controller to convert the energy into electrical current. A wattmeter was connected in series between the charge controller and 12V battery to read voltage, current, power and watthours. Two multimeters were connected to read voltage and current independently, which then fed data into a PC using a serial to USB output. The 12V battery was then used to power a Prusa I3MK3 3D printer that could then print medical supplies.

Line diagram of the bike generator system.

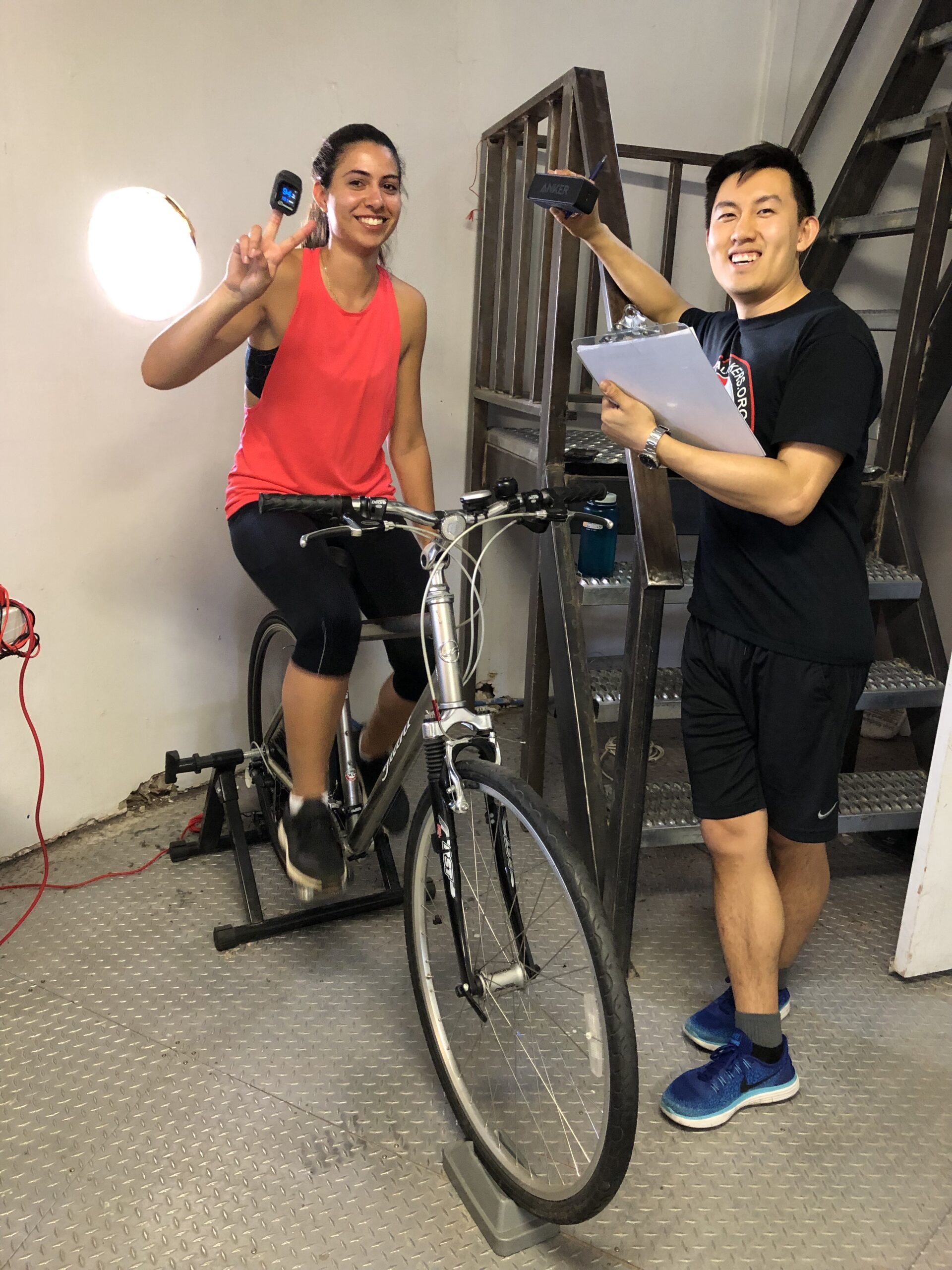

A photo of myself during a trial on the bike generator system in the Mars hub.

EXPERIMENTAL METHODS

Setup:

- IRB approval was obtained from the Memorial University of Newfoundland (partner researcher), and consent was obtained from all research projects.

- 5 crew members were subject to 1 hour on the bicycle per day, for a total of 2 days per mission, x2 missions (20 hrs total data).

- Baseline data for each subject was collected, including baseline and maximum heart rate, and Likart scale on biking experience.

During Experiment:

- The subject's heart rate was recorded at 5 minute intervals to ensure maximum heart rate was not exceeded.

- Multimeters were monitored to ensure consistent power output.

- Total power output was collected over time.

Post-Experiment:

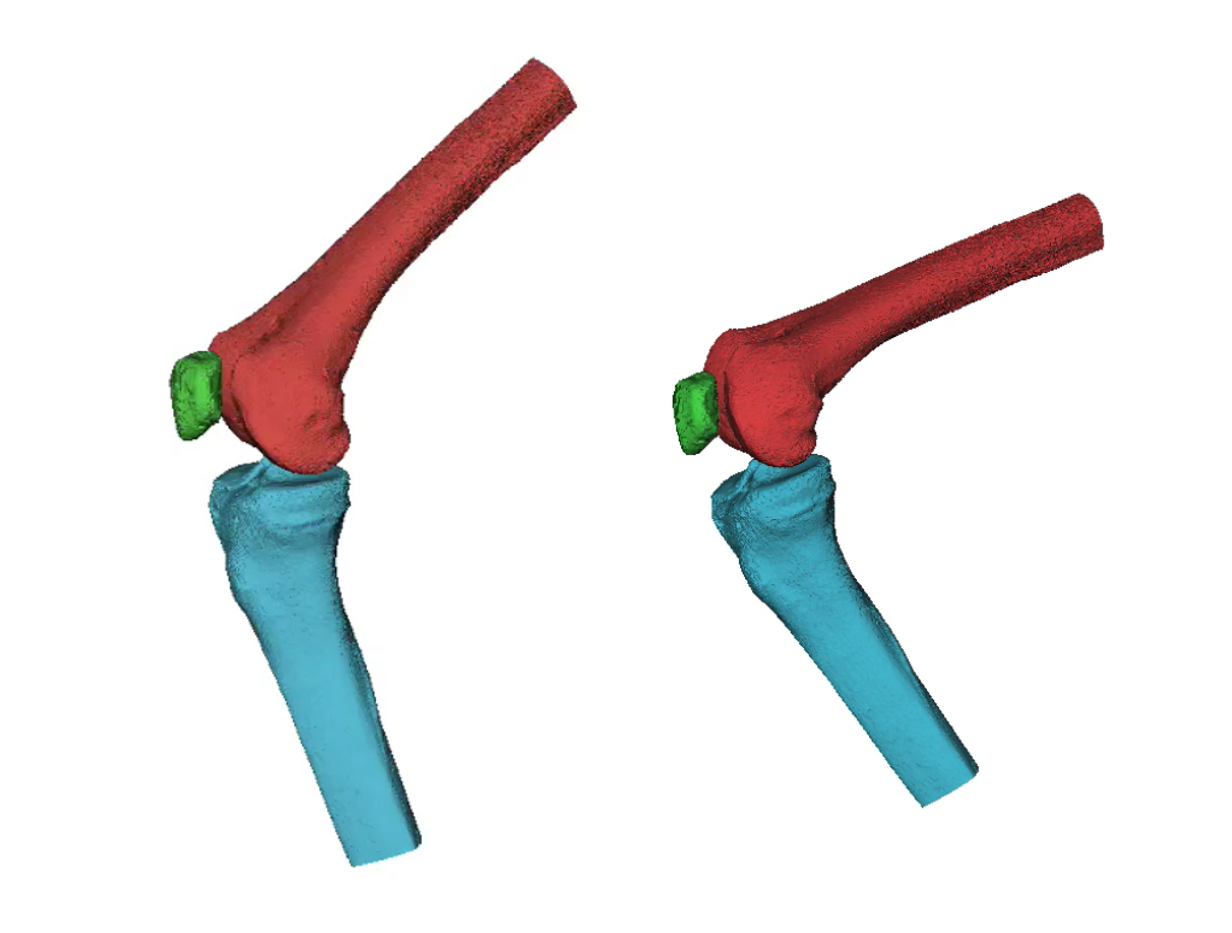

- After sufficient battery charge (~5-6 hrs on the bicycle), the battery was drained by 3D printing medical supplies such as customized mallet finger splints (previous ISS print), and a replacement knob for the 3D printer's LCD.

- The functionality of the 3D printed medical suppliers were tested by independent assessors post-mission who are certified healthcare providers.

- Data reduction and statistical analysis of power outputs.

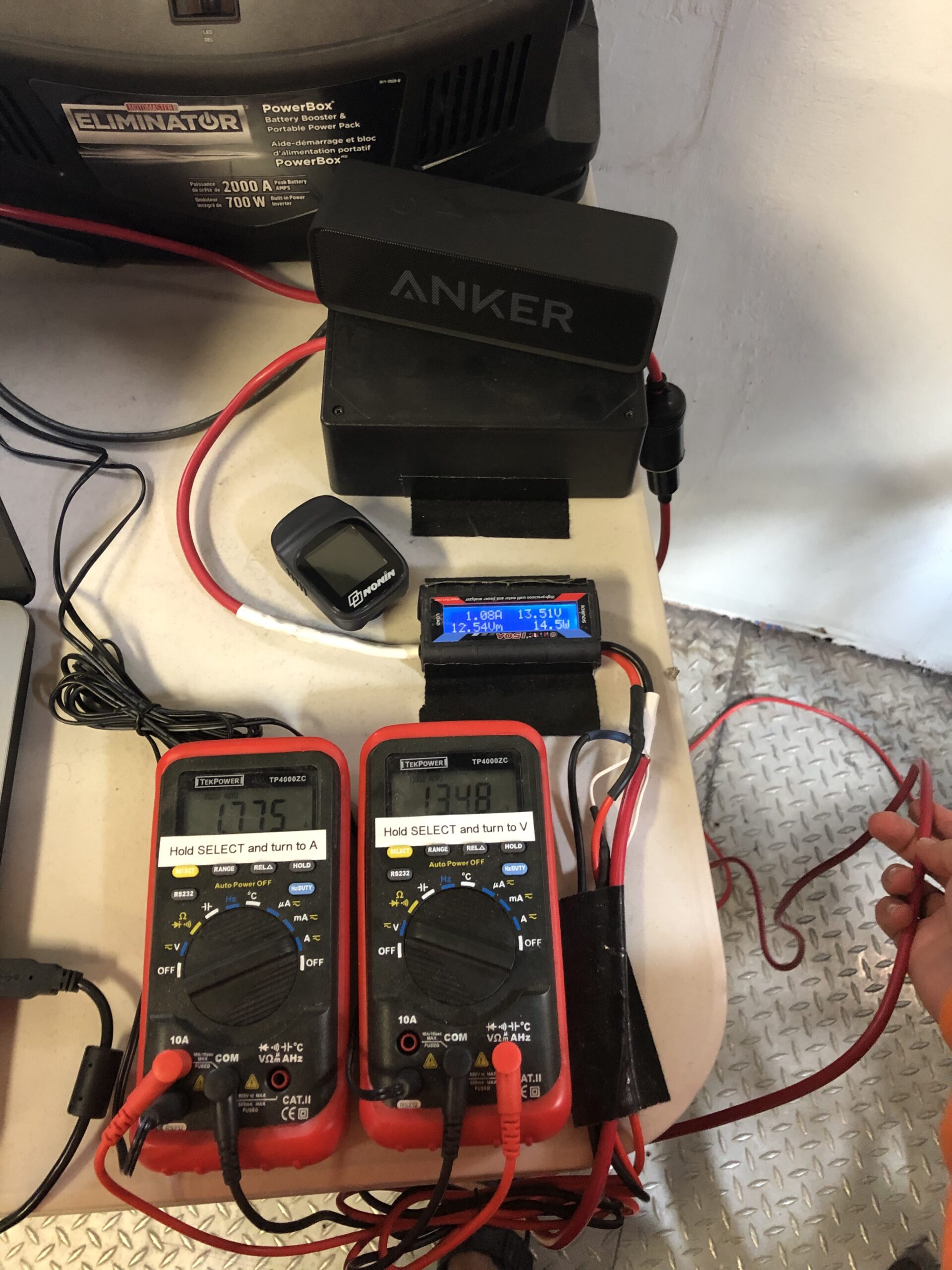

Pedal-a-Watt generator system and electronics troubleshooting

Electronics setup, battery, and me on the bike with a finger pulsometer to measure heart rate

OUTCOMES & FUTURE WORK

The goal of this experiment was to determine whether electricity generation via working out was technically feasible. With confidence, we were able to conclude that yes, it is technically feasible. However, more work is required to refine the system, experimental methods and outputs.

Power production was modest and highly variable among subjects, with a mean of 25.3 Watt-hours and standard deviation of 16.7. Despite the variability and experimental limitations, it was sufficient to power a 3D printer to make functional medical supplies. Data analysis is still underway. The manuscript was put on hold as other COVID-related projects took priority.

Limitations:

- System efficiency was <70%.

- Power requirements may be different aboard the ISS in a microgravity environment.

- Our system did not include a vibration isolation system, like the CEVIS.

- Astronauts are unlikely to generate the same power output due to deconditioning.

Future Work:

- Improve system efficiency (perhaps via use of lithium ion battery).

- Explore CEVIS-compatibility.

- Continue data analysis and repeat experiment to reduce variability.

KEY TAKEAWAYS

Prepare for issues in the field. The system took 2+ months to build and test at home, then had to be taken apart to ship to Utah. Upon rebuilding, we faced issues with specific system connections (e.g. voltage was reading incorrectly) which required troubleshooting on the spot in order to continue with the experiment. This is bound to happen in any user test or demo environment, and it is important to be prepared with extra tools, materials and workarounds.

VIEW MY OTHER PROJECTS:

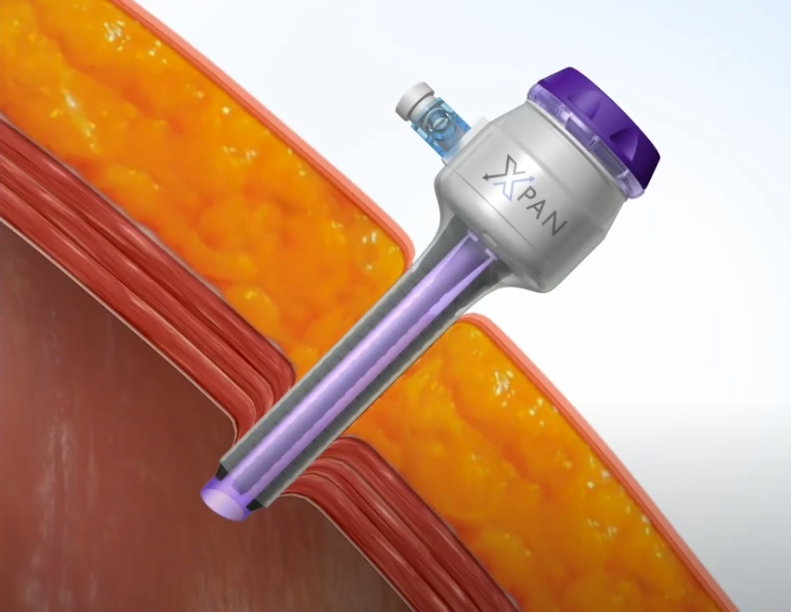

Xpan: A Less Invasive Surgical Access PortPhysical Products

Xpan Brand Revitalization: Logo & Web DesignDigital Products

New Start Foundation: Logo & Web DesignDigital Products

Fino: A Youth Financial Education AppDigital Products

AR Needle Guidance System for Heart Fluid AspirationPhysical Products

100% Reusable Faceshields for COVID-19Physical Products